Acid Resistance Epoxy Coating

Acid Resistance Epoxy Coating Specification

- Melting Point

- (Industrial Coating)

- Application

- Industrial surfaces chemical plants warehouses laboratories storage tanks

- Appearance

- Viscous liquid before application; smooth cured surface

- Feature

- High resistance to acid corrosion durable and long-lasting superior adhesion

- Grade

- Industrial Grade

- Usage

- Apply to clean and dry surfaces as a protective coating for acid-prone environments

- Purity

- Defined by industry standards; typically high-performance components

- CAS No

- (Composite material)

- Other Names

- Acid-Resistant Epoxy Paint Acid-Proof Coating

- Structural Formula

- (Composite material)

- Color

- Customizable; typically gray white or black

- Molecular Formula

- (Composite material)

- Chemical Name

- Epoxy Resin with Acid-Resistant Hardener

- Molecular Weight

- (Composite material)

- Ph Level

- Neutral (Non-corrosive during application)

- Water Content

- Low

- Poisonous

- Non-poisonous when cured; handle with care during application

- Type

- Epoxy Coating

- EINECS No

- (Composite material)

- HS Code

- 39073000

- Physical Form

- Liquid (before curing)

- Smell

- Mild Epoxy Odor

About Acid Resistance Epoxy Coating

Specification

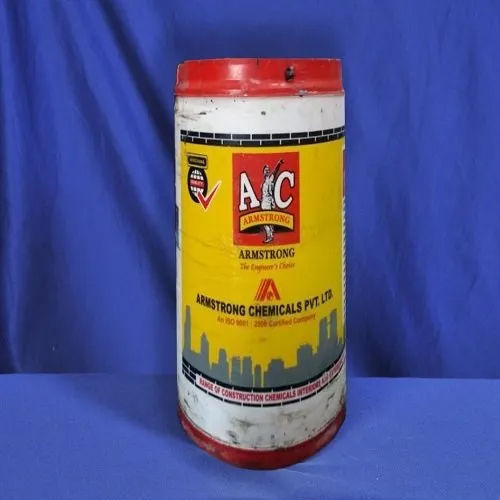

| Usage/Application | Industrial |

| Packaging Size | 3 kg |

| Grade Standard | Industrial Grade |

| Category | Floor Coating |

| Packaging Type | Plastic Container |

| Country of Origin | Made in India |

| Manufacture By | Arm Strong |

- For floor-1.5 kgs./M21 mm thick. For walls - 750 gms/M2 5mm thick, in 2 coats.

- Wherever concentrated acid exposure is expected, double the thickness is needed.

- Pack : 3, 15 & 30 Kgs.

FAQs of Acid Resistance Epoxy Coating:

Q: What type of surfaces can the Acid Resistance Epoxy Coating be applied to?

A: The Acid Resistance Epoxy Coating can be applied to industrial surfaces, chemical plants, warehouses, laboratories, and storage tanks.Q: Is the Acid Resistance Epoxy Coating non-corrosive during application?

A: Yes, the Acid Resistance Epoxy Coating has a neutral pH level and is non-corrosive during application.Q: What is the appearance of the Acid Resistance Epoxy Coating before and after application?

A: The Acid Resistance Epoxy Coating is a viscous liquid before application and cures to a smooth surface after application.Q: Can the color of the Acid Resistance Epoxy Coating be customized?

A: Yes, the color of the Acid Resistance Epoxy Coating is customizable, with typical options being gray, white, or black.Q: Is the Acid Resistance Epoxy Coating poisonous?

A: The Acid Resistance Epoxy Coating is non-poisonous when cured, but it should be handled with care during application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Epoxy Floor Coatings Category

Rainseal Bt Prime Bitumen Primer

Feature : Waterproofing quickdrying excellent adhesion

Appearance : Thick liquid smooth texture

Grade : Industrial grade

Type : Primer

Poisonous : Other, Nonpoisonous if used as directed

Color : Other, Black or dark brown

Roofcare EPS Polysulphide Modified Epoxy Coating

Feature : Polysulphide modified epoxy for enhanced durability and adhesion

Appearance : Smooth viscous coating compound

Grade : Industrial Grade

Type : Polysulphide Modified Epoxy Coating

Poisonous : Other, Nonpoisonous under normal usage

Color : Other, Gray or customized

Epoxy Primer Floor Coating

Feature : High adhesion chemical resistance durability

Appearance : Smooth liquid with customizable color

Grade : Industrial grade

Type : Floor coating primer

Poisonous : Other, Nontoxic once cured hazardous in liquid form

Color : Other, Varies (Customizable)

Rapidstong Tf 300 Resin Rich Epoxy Flooring Compound

Feature : High strength durable chemicalresistant seamless finish

Appearance : Viscous liquid or semisolid for flooring application

Grade : Industrial Grade

Type : Epoxy Flooring

Poisonous : No when cured properly, Other

Color : Other, Typically grey or customized upon request

Send Inquiry

Send Inquiry