Water Thinnable Epoxy Coating

Water Thinnable Epoxy Coating Specification

- Type

- Water-based epoxy resin

- Physical Form

- Liquid

- Molecular Formula

- Not applicable; mixture of components

- Usage

- Used in industrial commercial and residential sectors for corrosion resistance floor coatings and surface protection

- Structural Formula

- Not applicable; mixture of components

- Ph Level

- Near neutral or slightly alkaline depending on formulation

- Chemical Name

- Not a single chemical; formulated resin blend

- Grade

- Industrial grade commercial grade

- Boiling point

- No specific boiling point; depends on formulation

- Application

- Protective coatings for concrete metals and industrial surfaces

- Poisonous

- No; non-poisonous when cured properly but components may require safe handling

- Smell

- Mild odor due to water-based components

- Color

- Varies; customizable based on application (e.g. clear white or pigmented)

- Molecular Weight

- Not applicable; mixture of components

- Melting Point

- Not applicable; liquid at room temperature

- EINECS No

- Not applicable; mixture of components

- HS Code

- 3907.30.00

- Water Content

- High (water-based formulation)

- Purity

- Varies depending on formulation; typically above 95% active ingredients in non-volatile content

- Other Names

- Water-based Epoxy Coating Waterborne Epoxy Coating

- CAS No

- Not applicable; mixture of components

- Feature

- Low VOC easy application excellent adhesion environmentally friendly

- Appearance

- Smooth liquid various colors

About Water Thinnable Epoxy Coating

Specifications:

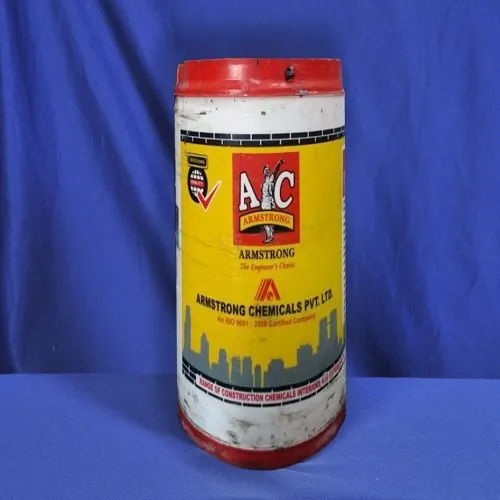

| Brand | Armstrong Chemicals Private Limited |

| Usage/Application | Industrial |

| Packaging Size | 5 kg |

| Coverage Area | 70 to 80 sft per litre per coat |

| Packaging Type | Bucket |

| Country of Origin | Made in India |

| Manufacture By | Arm Strong |

Versatile Protection for Varied Surfaces

Water Thinnable Epoxy Coating serves as a robust protective layer for concrete, metals, and other industrial surfaces. Its advanced formulation ensures long-lasting resistance to corrosion and physical wear, making it suitable for use in warehouses, factories, commercial spaces, and residential areas.

Eco-Conscious Industrial Solution

Designed with low VOC emissions, this water-based epoxy coating minimizes environmental impact and odor. Its near-neutral to slightly alkaline pH and non-poisonous nature when cured properly highlight its suitability for spaces prioritizing occupant safety and sustainability.

Easy Application and Customizable Appearance

Available in different colors and finishes, including clear and pigmented types, Water Thinnable Epoxy Coating offers both functionality and aesthetics. The liquid form promotes user-friendly application, either by brush, roller, or spray, ensuring smooth coverage and excellent adhesion.

FAQs of Water Thinnable Epoxy Coating:

Q: How is Water Thinnable Epoxy Coating applied to surfaces?

A: This coating is typically applied using brushes, rollers, or sprayers. Its liquid form ensures smooth and even coverage, making it suitable for use on concrete floors, metal structures, and other industrial surfaces. Proper surface preparation enhances adhesion and performance.Q: What are the main benefits of using water-based epoxy coatings over solvent-based alternatives?

A: Water Thinnable Epoxy Coating offers low VOC emissions, easy application, and a mild odor, making it environmentally friendly and safer to use. It provides excellent adhesion, corrosion resistance, and is customizable in color to suit various applications.Q: When should Water Thinnable Epoxy Coating be used for industrial or commercial projects?

A: This epoxy coating is ideal when protection against corrosion, chemicals, and physical abrasion is required for floors, equipment, or infrastructure in warehouses, factories, garages, and similar spaces. Its eco-friendly formula is especially beneficial in areas with occupancy concerns.Q: Where is Water Thinnable Epoxy Coating commonly applied?

A: It is widely used in industrial, commercial, and residential sectors, particularly for coating concrete floors, metal surfaces, plant equipment, and other high-wear surfaces requiring durable protection.Q: What process is followed for curing Water Thinnable Epoxy Coating after application?

A: After application, the coating is allowed to dry and cure, which typically involves air drying at ambient temperature. Curing may vary based on environmental conditions and specific formulation. Full chemical resistance and durability are achieved once completely cured.Q: Is Water Thinnable Epoxy Coating safe to use indoors?

A: Yes, being water-based and low in volatile organic compounds, it is suitable for interior applications. Once cured, it is non-poisonous and supports healthier indoor air quality compared to solvent-based products.Q: What customization options are available for the color of the epoxy coating?

A: The product can be tailored in appearance, including clear, white, or pigmented finishes, depending on aesthetic requirements or functional needs of the project.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Protective Coatings Category

Roofguard AB Acrylic Blended Bituminous Protective Coating

Usage : Apply using a brush roller or sprayer on roof surfaces for waterproofing and protection

Feature : Acrylicblended weatherresistant bituminous protective coating

Smell : Bituminous odor, Other

Appearance : Viscous black liquid

Grade : Industrial grade

HS Code : 32091000

Anti Efflorescence Coating

Usage : Apply directly on surface using brush roller or spray after proper surface preparation

Feature : Prevents the formation of white salty deposits enhances the durability of concrete and masonry surfaces waterrepellent

Smell : Mild or Odorless, Other

Appearance : Clear or slightly opaque liquid

Grade : Industrial Grade

HS Code : 3209.10

Roofbond Efc Primer Protective Coatings

Usage : Apply as a base coat before the main protective or decorative coating

Feature : Protects surfaces enhances adhesion weatherresistant

Smell : Mild, Other

Appearance : Viscous liquid

Grade : Industrial Grade

HS Code : 3208.10

Rainseal CFR Cellulose Fibre Reinforced Acrylic Elastomeric Coating

Usage : Apply with brush/roller/spray on clean and primed surface

Feature : Cellulose fibre reinforced waterproof durable UV resistant

Smell : Other, Mild acrylic odor

Appearance : Viscous liquid with smooth texture

Grade : Industrial grade

HS Code : 32091000

Send Inquiry

Send Inquiry